Business Solutions

Jacky’s Business Solutions LLC, is one of the divisions under the family-owned Jacky’s Group of Companies, which is now over 50 years old, caters to Business-to-Business customers across the UAE and the Middle East. With the Head office located in Dubai and professionally managed team of presales, sales, technical support, operations, and back-office team we provide total peace of mind to the customers. Across the Middle East, Jacky’s actively engage with a network of end users, resellers and solutions partners that are looking for digital solutions in the B2B space.

Jacky’s Business Solutions LLC provides customized and complex solutions for enterprise customers in the areas of Queue Management or customer/visitor journey solutions, Customer feedback solutions, Digital signage solutions, Meeting room booking solutions and Robotic process automation (RPA) focused on Government, Healthcare and Banking sectors.

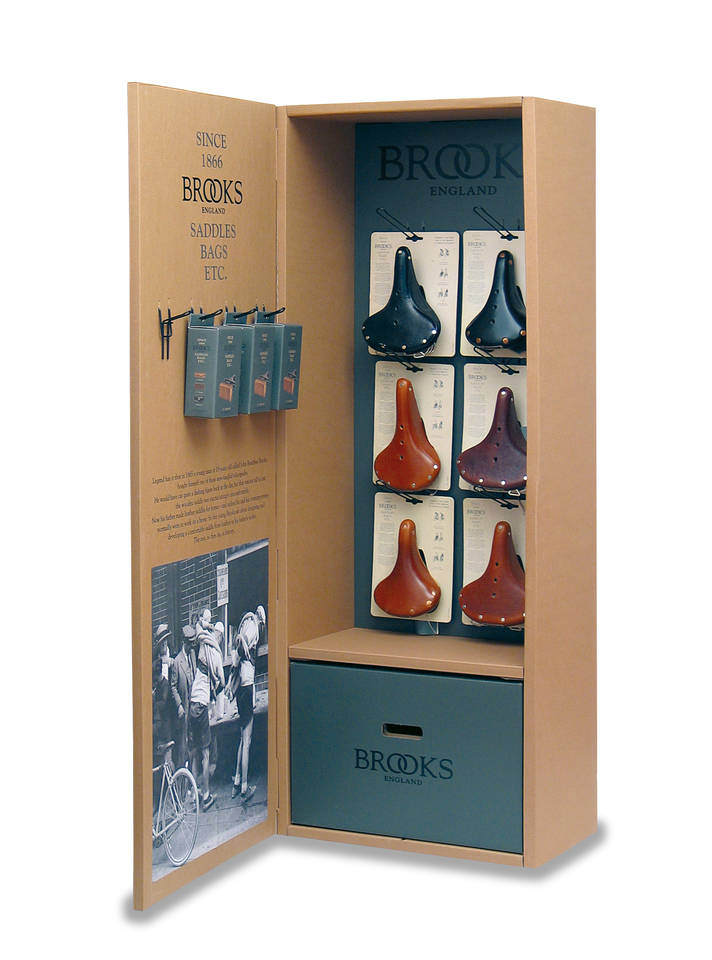

Jacky’s Business Solutions LLC a are market leaders for the world’s leading Humanoid Robots (Softbank Robotics), Telepresence Robots (Double Robotics), Personal assistance robots (Temi), commercial vacuuming robots (Whiz), Food delivery and dish collection robots (PUDU Robotics), Disinfection robots (PUDU Robotics), Escalator handrail sanitizers (WeClean), etc., for industry segments including, Government, Healthcare, Hospitality, Education, Retail, Telecom & Banking applications.

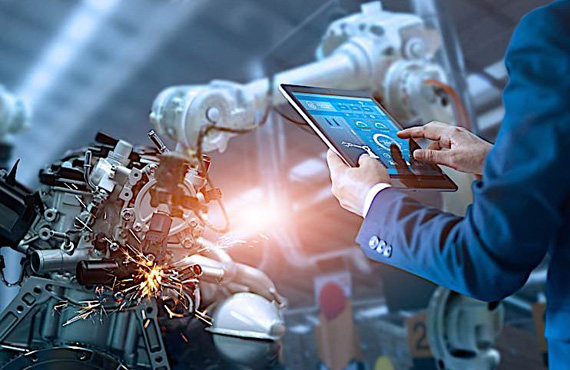

Jacky’s Business Solutions are leaders in sign, display, and graphics industry as well. As partners for HP’s Large Format printing solutions, Jacky’s sells to customers catering to segments like exhibition graphics, retail graphics, digital textiles, outdoor signage and traffic signage. We are also specialist and focusing on distribution of high-quality finishing and cutting products that are used in the sign & graphics, textile, and manufacturing industries in the Middle East and Africa Region through representations of brands like Zund, Flexa, EngView, and 3A composite.

Jacky’s distribute 3D printing products as well and work with brands like Massivit, BigRep and Makerbot across the Middle East region. Segments like education, manufacturing, prototyping and other segments where composite materials are being used are where we specialize.

Hospitality

An evolving industry and service preferences necessitate flexible solutions that are purposeful, proactive and profitabl...

Government

Jackys Business Solution is the premiere information platform on the smart use of technology. Our products can be used i...

Healthcare

Jackys business solution choose the best possible support for your patient. Learn how our brands protect, support and sa...

Education

Our Education solution provides the continued expansion of the Science of Education, offering products and resources for...

Print Service Providers

Artists, writers, graphic designers and office workers all depend on printing technologies to reproduce their work. Jack...

Telecom

Jackys Business solution optimization, personal services like Queue Management System, Microsoft Surface pro and Navori.

Finance

Jackys Business Solution helps Financial Institution innovates using our qualified brand such as Queue Management system...

Textile & Garments

Textile and Garment is a diverse and exciting field of the retail industry, and Garment Technologists are currently in h...

Interior Decor

With the help of Jackys Business solution products like BigRep 3D printer , Softbank Robotics, Canon, HP, Flexa, SAI sof...

Retail

Jackys Business Solution offer solutions to help make the customer experience better in a brick-and-mortar retail store....

Manufacturing

Jackys Business Solutions provides the productive products that power a growing, stable economy and a rising standard of...