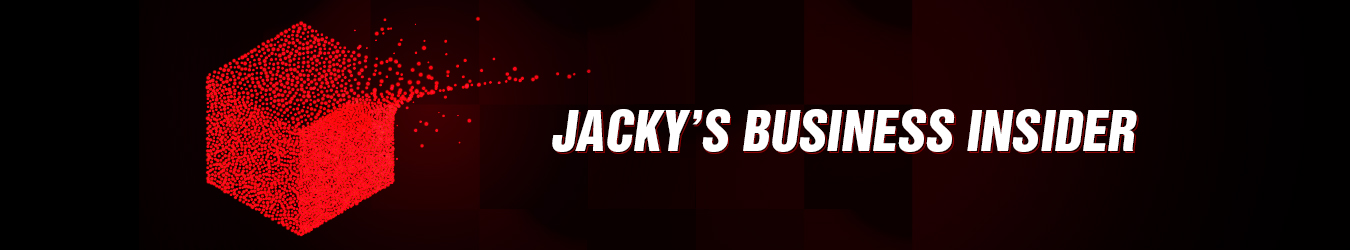

Our vendors, MakerBot has introduced a whole new way to create solid metal parts that can withstand high temperatures and extreme loads. The system can now print BASF Ultrafuse 316L Stainless Steel on MakerBot METHOD. BASF Ultrafuse parts combine the next level strength, rigidity, and durability needed for end-use parts and manufacturing tools.

Print solid metal parts with unbeatable rigidity, heat resistance (550°C max temp), and strength (561 MPa tensile) utilizing the MakerBot LABS GEN 2 Experimental Extruder. 316L stainless steel is one of the most popular types of steel because of its impressive level of corrosion resistance. Ultrafuse 316L packages 316L into a 3D printable filament which can be post-processed to produce 100% metal parts. Print tools and end use parts that can stand up to just about anything.

METHOD’s Heated Chamber delivers parts that are strong and accurate. METHOD’s Ultra-Rigid Metal Frame offers an outstanding surface finish that hides layer lines. It can also print the most complex geometries including internal cavities with soluble support, or use breakaway support for faster print times.

METHOD’s sealed filament bays help keep the material dry, resulting in better print quality and reliability. It comes with purpose-built toolheads for different material groups and applications, easily swappable in seconds and no tools required.

If you want us to find out more, email us on bridget.dsouza@jackys.com for more detailed and personalised discussions.