BigRep VIIO 250

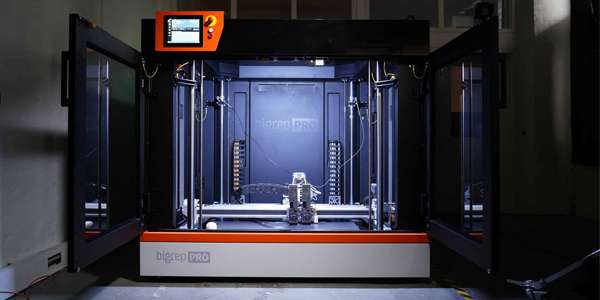

BigRep VIIO 250 Home / BigRep VIIO 250 BigRep VIIO 250 The large-scale BigRep VIIO 250 is a fully automated 3D printer for reliable continuous industrial manufacturing. To achieve this, the machine is built with breakthrough automation features: auto-calibration, auto-sequential printing, and automated filament handling to deliver maximized machine efficiency. Featuring dual Smart Manufacturing Extruders and an intuitive user machine interface with animated guides, using an industrial 3D printer has never been this easy. With the VIIO 250, spend less time printing and more time doing. Features 250 LITERS BUILD CHAMBER HEATED UP TO 50°C DUAL SMX EXTRUDERS FOR PRECISION AND SPEED PRINT ENGINEERING MATERIALS UP TO 350°C QUALITY IN LARGE-FORMAT: With a robust frame and components, plus an actively heated build chamber, VIIO 250 delivers industrial quality in large scale. LARGE & COMPLEX PRINTS: Dual SMX extruders tackle complex geometries, while continuous printing features can process up to 32 kg with hands-off production. ENGINEERING MATERIALS: Thanks to precisely controlled SMX extruders, VIIO 250 reaches up to 350°C for complex prints with engineering-grade materials. Industrial Automation Made Easy 01. Non-Stop High-Resolution Prints Discover the BigRep VIIO 250: A cutting-edge, fully automated 3D printer designed for continuous industrial manufacturing. Featuring breakthrough automation including Relay Mode for backup extrusion, auto print bed calibration, auto-sequential printing, and the Infinity Box for filament handling. Enhance efficiency and reduce production costs with dual Smart Manufacturing Extruders and an intuitive user interface. Revolutionize your production process with high-quality, energy-efficient prints in less time. Fully Automated Production For Every Industry 01. AUTOMOTIVE-GRADE PARTS Make robust components for a variety of automotive applications. Using materials of the highest caliber for engineering, the VIIO 250 prints robust, lightweight components. The exceptional precision, consistency, and sharpness facilitate advancements across the whole design process. 02. Functional Prototypes Validate parts and test designs prior to final manufacturing. With the open-material approach, you may recreate the final part precisely and select from a large selection of filaments. Reduce production expenses, iterate more quickly, and launch your goods more quickly. 03. Durable Tooling Make quick, inexpensive tooling for your manufacturing floor, such fixtures and jigs. The automation capabilities enable you to build geometrically difficult tools in-house with reliability. Overcome antiquated methods and produce tools as needed. Technical Specifications Technical Specifications Version BigRep VIIO 250 Build volume 1000 mm x 500 mm x 500 mm (x,y,z) Compatible materials BigRep ASA, BVOH, HI-TEMP, HI-TEMP CF, PA12 CF, PA6/66, PETG, PLA, PLX, PRO HT, TPU 98A (Open for 3rd party materials) Support materials BigRep BVOH (Open for 3rd party materials) Filament diameter 2.85 mm Extruders Dual Smart Manufacturing Extruders (SMX) Nozzles Tungsten carbide (0.4 mm, 0.6 mm) or polycrystalline diamond (1.0 mm) Nozzle diameters 0.4 mm, 0.6 mm, 1.0 mm Layer thickness 0.2 mm, 0.3 mm, 0.5 mm (Other layer heights supported through slicer software) Extruder temp Up to 350°C Build chamber temp 30-50°C Print bed temp Up to 120°C Removable print surface SWITCHPLATE prime, SWITCHPLATE select Max print speed Up to 500 mm/s Max throughput Up to 166 cm³/h Position accuracy ±0.004 mm in XY, ±0.003 mm in Z Drive technology Stepper motors with steel reinforced belt drive in XY, Spindle with self-lubricating nut in Z Connectivity 10/100/1000 Base T Connection Ethernet Protocol, USB Port, BigRep Connect Ready with remote monitoring/control features Slicing software BigRep BLADE Machine control BigRep Kreuzboard HMI 12.1” touchscreen Camera Built-in chamber camera for real time remote monitoring Power supply 208-240 V, 50/60Hz, 16 A Power consumption Average (while printing): 660W, Peak: 3200W External dimensions 1634 mm x 1069 mm x 1829 mm (x,y,z) Weight 560 kg printer in base configuration, 62 kg Infinity Box Related Products BigRep ALTRA280 View BigRep IPSO 105 View BigRep One View BigRep Studio G2 View BigRep Pro View

Bigrep

BigRep is the world’s largest 3D printer with 1m3 built volume. It works on FDM technology that can use open-source PLA biodegradable plastics. PLA comes in a variety of colors and types. PLA is also the cheapest and most used 3D printing filament.

MakerBot

Discover UltiMaker’s newest 3D printing solutions: Desktop 3D printers, software, and materials for streamlined production and unlimited innovation.

BigRep Expands Into High-Temperature Large-Format By Acquiring HAGE3D

Jacky’s Business Solutions’ vendor, BigRep, is strengthening its leadership position in the industrial open AM sector by acquiring HAGE3D GmbH, the AM subsidy of HAGE, an advanced engineering company with 40 years of experience in reliable, large-format specialty machine building. With this merger, two high-quality, open AM platform providers from Germany and Austria are joining forces under one roof, combining their strengths for their clients and partners by offering a full solution range comprising reliable hardware, intelligent software, virtually limitless materials, and peace of mind service offerings. BigRep and HAGE3D together offer a superior portfolio of industrial 3D printers with up to one cubic meter build volume handling the full range of standard, technical, and high-performance thermoplastic materials in low-, mid- and high-temperature build chambers. Customers of both BigRep and HAGE3D can now benefit from an even broader range of printable materials enabling industrial AM applications in multiple industries where complex, strong, large-format parts are needed, such as Automotive and Aerospace. In short, the acquisition combines HAGE3D’s high-quality, high-temperature hardware with BigRep’s holistic approach to AM, integrating intelligent software and industrial services. Together, BigRep and HAGE3D are taking open, large-scale industrial FFF additive manufacturing to the next level, forming a new global powerhouse. To find out what this means for your additive manufacturing, please reach out to Bridget Dsouza on bridget.dsouza@www.jackys.com.

Jacky’s Business Solutions introduces special promotion on Ultimaker Makerbot METHOD XL

The continuous quest for stronger, more versatile, and larger-scale materials has led to the evolution of 3D printing technology. With the recent launch of the ABS Carbon Fiber material designed for the Ultimaker Makerbot METHOD XL, a new era of composite 3D printing has dawned. This groundbreaking material promises to revolutionize the way we approach large-scale projects, offering an unprecedented combination of strength, accuracy, and convenience. To celebrate this, Jacky’s is offering free ABS CF spool with every purchase of the METHOD XL printer, your gateway to exploring the immense potential of this cutting-edge technology. The METHOD XL, already known for its exceptional performance, now becomes a powerhouse when paired with ABS Carbon Fiber, offering a one-of-a-kind experience that redefines what's possible in the world of additive manufacturing. ABS Carbon Fiber opens the door to a multitude of opportunities for creators, engineers, and innovators. This innovative material combines the best of both worlds: the performance-enhancing properties of carbon fibre and the reliability of ABS plastic, resulting in a material that not only boasts remarkable strength and durability but also retains the familiar ease of printing associated with the Ultimaker Makerbot METHOD 3D printers. One of the standout features of ABS CF is its compatibility with RapidRinse technology. RapidRinse ensures that the post-printing process remains efficient and hassle-free, allowing you to focus on your projects. The crown jewel of this promotion is the METHOD XL's extra-large print bed. This game-changing feature provides ample space for creating larger-than-life prints or optimizing your workflow by producing multiple parts simultaneously. With METHOD XL and ABS CF, you can bring your boldest ideas to life without sacrificing structural integrity. The fusion of technology, material innovation, and limitless creativity is the driving force behind the world of 3D printing. With the special promotion that marries Ultimaker Makerbot METHOD XL and ABS Carbon Fiber, you're not just getting a printer and a spool – you're acquiring a gateway to a new dimension of production possibilities. If you want to find out more, reach out to Bridget Dsouza on bridget.dsouza@www.jackys.com.

How to choose which features you need on a modular BigRep One

The BigRep ONE is a modular large-format FFF 3D printer designed to produce high-quality, long-lasting parts while saving you time and money. With a massive build volume of one cubic meter and versatile modular feature configurations, it’s perfect for a wide range of applications, including prototypes, furniture design, creative exhibitions, automotive components, tooling, and more. The latest version, the BigRep ONE.4 can be configured with various modes and add-ons. Customize the specific large-format 3D printer for your current needs, while you also have the possibility to upgrade as those needs change in the future. It’s important to understand the BigRep ONE’s standard features and capabilities as a modular 3D printer, so you can adjust the ONE to meet your specific Additive Manufacturing needs. Single Mode is the most affordable option, a basic configuration with a single Power Extruder and a 1mm nozzle. This option is great for prototyping and testing large-scale prints on a lower budget, however, water-soluble support isn't possible in Single Mode. If you already have Single Mode, you can upgrade to as your needs change to print with two extruders instead of one. This is also necessary to install first if you want to print in twin mode. Dual Mode allows for dual extrusion. This is perfect for producing complex geometries when you need water-soluble support for easy removal after printing. Some customers prefer to keep different nozzle sizes on either PEX to avoid swapping out nozzles for different prints. Another advantage of dual extruders is having two different primary materials readily loaded for fast switching between filaments. Twin mode is perfect when you want multiple prints of the same geometry, speeding up your output by 100% and doubling your production. As both extruders work simultaneously, you can print two versions at once, cutting costs and reducing time-to-part by 50%. With Twin Mode, each extruder can print within one-half of the build volume, so Dual or Single Mode is required for larger prints needing build volumes over 0.5m2. If you want to find out which configuration is right for your business and which add-ons to go for, reach out to Bridget Dsouza on bridget.dsouza@www.jackys.com for more details.

Ultimaker undergoes new branding after merger with MakerBot

Last year, Ultimaker announced the merger with MakerBot, combining the power of two leading 3D printing companies to create one brand to shape the future of manufacturing and product development. Since then, the company launched the Sketch Large and S7 3D printers, strengthening its offerings for the educational and professional markets. Ultimaker has now announced a new brand identity, reflecting its strategic vision and new brand architecture. Under the UltiMaker brand, the S and Method series 3D printers will support manufacturing, product development and other professional applications. As one of the world’s most popular professional 3D printers, the S series will continue to offer the widest variety of materials on the market, making it flexible for a multitude of uses, while the Method series will focus on more specific manufacturing applications that can benefit from access to a heated chamber, high-temperature thermoplastic, and a high level of dimensional accuracy. Meanwhile, the MakerBot brand will remain operational as a sub-brand within the education sector, with the Sketch series targeted at K-12 learning. With one of the most comprehensive education ecosystems in 3D printing, MakerBot will continue to empower educators and students to take their ideas to the next level. This new brand architecture is designed to ensure that you can easily find the products and applications best suited to your needs. All UltiMaker hardware and software products are expected to be rebranded over the next 12-18 months. To explore how MakerBot can meet your 3D needs in the education sector, please reach out to bridget.dsouza@www.jackys.com.

MakerBot introduces CloudPrint 2.0

Our 3D printing vendor, MakerBot has introduced its latest version of CloudPrint. With enhanced user interface and upgraded features, it offers a faster, more secure, and more advanced print preparation and management solution. Offering an easy-to-use and secure workflow, CloudPrint gives users better control and management of their prints from start to finish. It allows users to get the printing started quickly and monitors progress with a live feed from the onboard camera. The updated CloudPrint 2.0 makes it easy to print right out of the box with pre-set print modes. Simply upload your models and let the software handles the setup based on your needs. CloudPrint has hundreds of modifiable parameters for advanced users. The new software’s Smart Arrange, Smart Orient, and Print Mode features are optimized to let the application automatically handle the setup based on individual user’s needs allowing them to choose from hundreds of modifiable parameters and save custom print mode for the next job. If you want to explore the full features and updates, reach out to Bridget D’Souza on bridget.dsouza@www.jackys.com. MakerBot introduces CloudPrint 2.0

6 considerations for purchasing a Large-Format 3D Printer

Our vendor, BigRep, has put together a very useful checklist of 6 things you need to consider before purchasing a large format 3D printer. There are several factors to consider before purchasing a large format 3D printer. Since there isn't a 3D printer that will fit every single application that you may have, it is important to understand what these application(s) are before considering your purchase. When purchasing a large printer, you also need to understand that the printer will take up quite a bit of space and will have electrical requirements. But it is just as important to think about your usage, the material requirements, software required, how the print will be supported and, obviously, the budget. So here are the top 6 considerations before purchasing a large-format 3D printer like BigRep. Application: The first and most basic question to ask yourself is “what do I want to 3D print and why?” Understanding this basic question first will help you identify opportunities and where you can benefit most from a large-format 3D printer. Materials: When you compare materials that you will print with, you should consider if you want your system to be a closed or open-source 3D printer. Closed systems require you to only use that printer’s material and locks you out of using 3rd party material. An open-source system allows you to use any material within the specs of the printer. Space and Environment: Large-format 3D printing means big 3D printers. The obvious question is, “do you have the space for it?” BigRep 3D printers work great on the shop floor, in labs and offices, and more. Depending on the environment where the printer will sit, you might want to consider whether you will require a climate-controlled room. Will humidity be a factor in the space? Are there particles floating around from other equipment? What material will I mainly be printing with? These factors can influence the outcome of the print. If the 3D printer is in a lab that is enclosed, then you can probably get away with an open frame system. Software: Almost every equipment manufacture has its own software that will set up the part to be built and sliced but some 3D printing companies are also open source and allow you to choose any slicing software. This comes with both advantages and disadvantages. Maybe you already have a software you are familiar with and want to continue using it. The software that comes with the printer, like a BigRep 3D printer is pre-loaded with profiles for materials and settings for the printer, making it very user friendly to start prints quickly. Local Support: Having local support is often an invaluable asset to any 3D printing company. Ask for references, talk to customers who are using the printers and understand their experience working with the company and if the level of service makes or exceeds your expectations. When you invest in an industrial large-format 3D printer, you expect the level of support to match the price tag of the printer. For BigRep and a few other 3D printers we represent, you can count on our support. Budget: Investing into a large-format 3D printer requires more than just what is mentioned above, but one of the most important questions to ask is, “what is my budget?” Try to be open when it comes to purchasing, because if you only have a certain dollar amount to spend but then that purchase a lower cost option that becomes more of a headache than an investment, was it worth it? You can read the full details on each consideration on their blog. Our teams can be very helpful to help you evaluate what your needs are and whether you need a large format 3D printer or if you do, you have the space for it. Please send an email to support@cuttingedge.solutions to set up a consultation. 6 considerations for purchasing a Large-Format 3D Printer

MakerBot announces a new 3D guidebook for educators

We are pleased to share the latest instalment of the MakerBot Educators Guidebook, the 3rd edition of MakerBot’s definitive guide to 3D printing in the classroom – over 150 pages available to you for free. This popular and easy-to-use guide for 3D printing from our vendor MakerBot covers a crash-course in 3D printing and how to begin integrating it into the classroom, projects spanning robotics, engineering, mathematics, science as well as projects for art, history, and music, It also includes a collection of techniques and tricks developed by educators already experienced with 3D printing. Here is a list of the areas the new guide covers: How to start 3D Printing in the Classroom Breaking down the 3D Printing Process Curriculum Project Ideas Teachers’ Tricks of the Trade 3D Printing within Professional Industries You can download the guide here. If you want to reach out to our team to find out more about MakerBot, please send an email to bridget.dsouza@www.jackys.com to set up a consultation. MakerBot announces a new 3D guidebook for educators