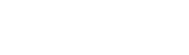

G3 cutter overview

The 11 different cutter sizes of the G3 line let you select the perfect machine size for all your production needs – no matter the area of application, product, or whether you produce small runs, large runs, or prototypes. Our digital cutting systems are intelligent, efficient, and ready for the future.

|

|

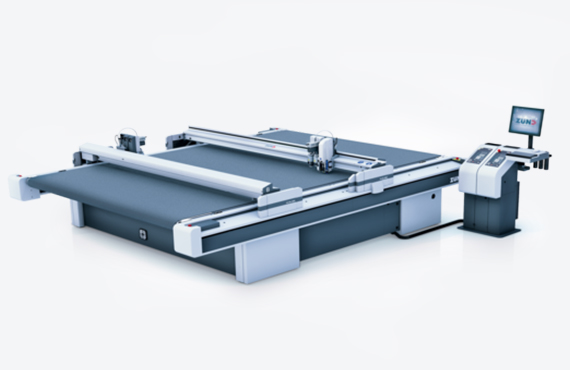

User-friendly ergonomics and operation

Our customers' requirements are taken into account during the G3's production and design. The end effect is straightforward, approachable, and ergonomic operations. The G3's sophisticated safety features actively aid the user and only get in the way when it's absolutely required.

|

|

Efficient tool management

You may configure the necessary tooling using Zünd's characteristic modular design in a few simple, rapid steps. You may respond instantly to changes in production requirements with adjustments and upgrades because to the resulting flexibility, which helps you save both time and money. The G3 cutting system provides optimum value retention and is a secure investment.

|

|

|

|

|

Quality at the highest level

The G3 flatbed cutter is a highly accurate machine. Everything from drive systems to blades is properly coordinated thanks to revolutionary technologies. Produce your jobs at the finest quality possible while remaining inexpensive and efficient. Your clients will be overjoyed with the results. |

|

Maximum productivity

The G3 cutting system's overall productivity is unsurpassed. We accomplish this by utilizing clever control technology, durable machine components, and smart cutting technology. Every component is well coordinated |

|

|

|

|

Unsurpassed price-performance ratio

The G3 cutter series has an excellent price-performance ratio. We exclusively employ cutting-edge technology and high-quality components. No competition in the industry can match the G3 cutter's flexibility, dependability, and quality.

|

G3 cutter sizes

Choose from 11 different sizes to select the perfect machine for your application.

|

|

Length (in mm/in)

1600, 2500 / 63, 98

Too big for your application? Consider an S3 digital cutting system

|

Length (in mm/in)

2500, 3200 / 98, 126

Would you like to double your productivity?

Consider a D3 digital cutting system

|

Length (in mm/in)

1600, 3200 / 63, 126

Too big for your application? Consider an S3 digital cutting system

|

Length (in mm/in)

1600, 3200 / 63, 126

Too big for your application? Consider an S3 digital cutting system

|

Length (in mm/in)

1600, 2500, 3200 / 63, 98, 126

Too big for your application? Consider an S3 digital cutting system

|

|

Find out more |

Find out more |

Find out more |

Find out more |

Find out more |

Zünd G3 – perfection is in the details.

Zünd cutters are high-precision machines. All components – from drive system to cutting blade – are designed and manufactured to work together perfectly. This lets you produce efficiently and wow your customers with perfect results.

Modular tooling system: Determine which functions your G3 cutter must execute and design your Zünd modular tooling accordingly.

Integrated tool initialization: Determine which functions your G3 cutter must carry out and configure your modular Zünd tooling accordingly.

Optimal material hold-down: Determine which functions your G3 cutter must do and setup your modular Zünd tooling to meet those requirements.

Process materials up to 110 mm/4.3 in thick: A G3 cutting system can process materials up to 110 mm/4.3 in thick. The G3 can be adjusted with a beam height of 60 or 120 mm/1, 2 or 4 in, depending on your needs. This means that your production workflow will be more adaptable and versatile.The router bit/tool changing is automated: The automated router bit/tool changing ARC drastically decreases setup times and simplifies tool handling. The magazine can hold up to eight different cutting, polishing, or engraving bits. After each use, the processing bits are automatically removed, clamped, initialized, and cleaned. The ITI initialization mechanism verifies the zero-point following each tool change, assuring fully consistent routing depths.

Modular, flexible, and adaptable high-performance modules

The right modules & tools for every application.

|

|

|

|

|

Compatible with G3, D3

|

Compatible with G3, D3

|

Compatible with G3, S3, D3

|

Compatible with G3, S3, L3, D3 |

|

Wheel Knife Tool

|

V-Cutting Tool - VCT2

|

V-Cutting Tool

|

Universal Routing Tool

|

|

Low-maintenance tool for single-ply cutting of glass and carbon fiber as well as technical textiles.

|

Tool with nine different cutting angles. Perfect for 3D designs made of polyester fiberboards and acoustic panels. |

Perfect for producing complex, 3D structural designs made of twin-wall sheets, cardboard, or foam.

|

Cost-effective routing and engraving tool.

|