The unique alloy - AlMg1.

3A COMPOSITES is the only manufacturer using an AlMg1 alloy for the DIBOND® cover layers

Your advantages:

-

sturdy material

-

especially for 3D applications by using the routing and folding technique

-

excellent processing characteristics

-

advanced corrosion resistance

The special Polyester coating system.

-

stove lacquered according to ECCA - Standards

-

constantly high quality of colour as well as colour consistency

-

only in-house lacquering at the 3A COMPOSITES site in Singen

-

very even, flat surfaces

-

perfect printing properties

-

no heavy metals in the lacquer system

-

conforms to RoHS, REACH and WEEE

The black core. UV-Blocker.

The two aluminium layers enclose a black polyethylene core

Your advantages:

-

UV-protection

-

material stability caused by the black core

-

excellent long term application outdoors

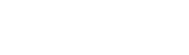

Convincing properties. Convincing in its application.

DIBOND® provides excellent properties for processing, handling, transport and installation

-

very high stiffness and dimensional stability - ideal for large format applications

-

three dimensional processing by using the routing and folding technique - offering various creative applications

-

processing and installation on the spot - pre-fabrication and flat transportation require only few steps from panel to 3D display

-

long term application outdoors - very low thermal expansion

-

weather resistant - applicable with temperatures between -50°C up to + 80°C

FAQ’s:

1. What is Dibond composite?

DIBOND® is the original aluminium composite sheet, comprising two 0.3 mm thick aluminium cover layers and a polyethylene or mineral core. It is lightweight – extremely rigid and strong, making it ideal for both indoor and outdoor applications.

2. What type of material is DIBOND?

Aluminium composite sheet, comprising two 0.3 mm thick aluminium cover layers and a polyethylene or mineral core.

3. What does 3A Composites make?

3A Composites Display Europe, an international division of the 3A Composites Group and part of Schweiter Technologies AG, is the leading manufacturer of sheet materials for the field of visual communication.

Thanks to a diversified range of products that include DIBOND® aluminium composite sheets, FOREX® and FOAMALITE® rigid foam plastic sheets, KAPA®, FOAM-X®, SMART-X® and GATORFOAM® lightweight foamboards, DISPA® and SWEDBOARD® paper boards, LUMEX® and HIPEX® PET sheets as well as PERSPEX®, CRYLUX®, CRYLON®, AKRYLON® and PERSPEX® XT acrylic glass sheets and IMPEX® polycarbonate sheets we can offer our customers a unique and perfectly coordinated range of products – and everything is from a single source.

4. How long will Dibond last outside?

we can provide warranty of 2-3-5 years depending on the product specification.

5. Can Dibond be used outdoors?

Yes, it can be used outdoors for applications such as signage, facades, wall panels and many other.

6. What are Dibond sheets used for?

The main areas of application for our products include digital and screen printing, exhibition booth construction and shop fitting, interior and shop design, photo mounting as well as signage, POS / POP displays and furniture construction.

7. Can you drill into Dibond?

Yes, Dibond can be cut, drilled or bent.

8. Can you paint on Dibond?

Yes, you can paint, print, or draw on Dibond.

9. Is DIBOND waterproof?

Yes, it is waterproof, but it depends also on how the material is installed.